In the modern manufacturing industry, precision and efficiency are critical factors for success. Slitting and rewinding machines play a vital role in converting large rolls of materials into smaller, more manageable sizes for various applications. Fangbang, a leading manufacturer with 36 years of experience in gravure manufacturing, offers a comprehensive range of slitting and rewinding machines designed to meet the diverse needs of film and paper processing industries.

Fangbang's slitting and rewinding machines are equipped with a 10.4-inch smart touchscreen and PLC control system, delivering precision control with slitting length error ≤0.1%. The user-friendly interface allows operators to easily set parameters, monitor production processes, and make adjustments as needed.

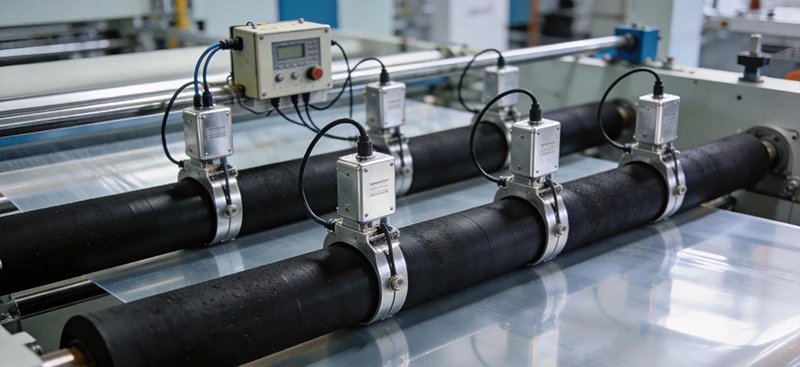

The machines feature an automatic web guiding system with photoelectric sensors, integrated with magnetic powder clutch and servo motor. This advanced tension control system ensures consistent material tension throughout the slitting and rewinding process, resulting in high-quality finished products.

With pneumatic mandrel winding paired with pressure roller assembly, combined with automatic waste material conveying system, Fangbang's machines achieve an impressive 99.2% winding neatness. This reduces material waste and improves overall production efficiency.

The FQ-LB slitter rewinder handles wide-web materials with high precision, delivering clean cuts and perfectly tensioned rolls for maximum production efficiency. Key specifications include:

A versatile performer, the FQ-2A offers precise slitting and smooth rewinding of various film types, ensuring optimal roll quality for downstream processes. Key specifications include:

The FQ-GB provides reliable slitting and rewinding for standard-width materials, known for its operational stability and ease of use in finishing lines. Key specifications inclu

This machine is suitable for slitting and rewinding various roll materials such as BOPP, PET, CPP, CPE, PVC, aluminum foil laminated with film and paper, etc. Key specifications include:

Fangbang's dust-free assembly workshop ensures core component cleanliness, achieving high factory acceptance rates. The company's precision machining equipment system includes German DMG five-axis machining centers and Japanese Mitutoyo coordinate measuring machines, extending tool life by 3 times.

Senior engineers provide on-site installation guidance, ensuring equipment foundation positioning accuracy with error ≤0.1mm. This ensures that the machines are installed correctly and operate at peak performance.

Fangbang's professional after-sales team provides round-the-clock online service, comprehensive pre-shipment machine testing services, and dedicated solutions for gravure printing presses. The company also provides detailed maintenance schedules and remote guidance services to ensure long-term machine reliability.

Slitting and rewinding machines are used in a wide range of industries, including:

These machines are ideal for processing flexible plastic packaging materials, ensuring precise slitting and rewinding for various packaging applications.

Slitting and rewinding machines play a crucial role in the production of diaper packaging, ensuring that materials are cut and rewound to the exact specifications required for diaper manufacturing.

The machines are also used in the production of masking tape, providing precise slitting and rewinding to create high-quality tape products.

Slitting and rewinding machines are essential for the production of pressure sensitive labels, ensuring that labels are cut to the correct size and rewound neatly for easy application.

In the tissue packaging industry, slitting and rewinding machines are used to process packaging materials, ensuring that tissue products are packaged efficiently and attractively.

Fangbang's slitting and rewinding machines are equipped with a high-precision servo control system, cutting accuracy is consistently maintained at ±0.1mm, ensuring smooth edges without burrs.

The machines are compatible with 12-500μm plastic films, metallized films, paper, and non-woven fabrics, supporting cutting widths from 8-1600mm.

Equipped with a 10.4-inch smart touchscreen and PLC control system, the machines support parameterized settings. Operators can master it proficiently after just 3 days of training.

Fangbang recommends cleaning the cutting blade system daily, inspecting pneumatic components weekly, and maintaining transmission parts monthly. The company provides detailed maintenance schedules and remote guidance services.

Closed-loop tension control and EPC web guiding systems, combined with pneumatic mandrels for uniform clamping, ensure winding edge neatness exceeding 99.2%, effectively reducing material waste.

Fangbang's slitting and rewinding machines offer precision, efficiency, and reliability for film and paper processing applications. With advanced features such as 10.4-inch smart touchscreen, 100% closed-loop tension control, and 99.2% winding neatness, these machines are designed to meet the highest standards of modern manufacturing. Whether you are in the flexible plastic packaging, diaper packaging, masking tape, pressure sensitive labels, or tissue packaging industry, Fangbang has the perfect slitting an

If you are interested in learning more about our slitting and rewinding machines or would like to discuss your specific requirements, please do not hesitate to contact us. Our team of experts is ready to assist you in finding the right solution for your business. We look forward to hearing from you soon!

Jan 29, 2026

High-Precision Slitting & Rewinding Machines - FANGBANG Industrial SolutionsJan 22, 2026

Why choose automatic Laminating MachinesJan 19, 2026

Electronic Axis Gravure Printing: Revolutionizing High-Speed Packaging Production