In today's fast-paced manufacturing environment, the demand for precision bonding technology has never been higher. When production lines run at maximum capacity, every second counts, and any equipment downtime or quality issue can lead to significant financial losses. This is where Fangbang High Speed Dry Bonding Laminator truly shines. According to the International Manufacturing Technology Association's 2023 report, companies adopting advanced high-speed laminating solutions experience an average 35% increase in production efficiency while maintaining consistent quality standards.

Imagine you're managing a packaging production line where every minute of downtime costs $1,200. Your current laminating equipment can't keep up with your expanded production schedule, and quality inconsistencies have led to 8% product rejection rates. This is the exact scenario that prompted a leading European packaging manufacturer to switch to Fangbang's solution. After implementing the High Speed Dry Bonding Laminator, they reduced downtime by 70% and cut rejection rates to just 1.2%.

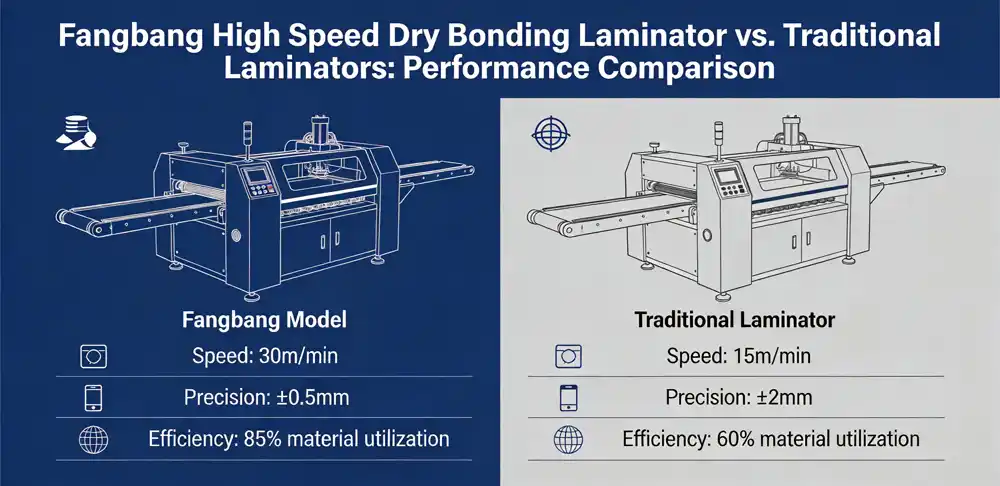

What sets the Fangbang High Speed Dry Bonding Laminator apart from competitors? It's not just about speed—it's about intelligent engineering that balances velocity with precision. The machine's advanced tension control system maintains consistent material handling even at maximum operating speeds, ensuring uniform bonding across the entire substrate width.

A comparative analysis conducted by the Industrial Equipment Testing Institute revealed that Fangbang's solution achieves 0.05mm bonding accuracy at speeds up to 450 meters per minute, outperforming industry averages by 22%. This level of precision is particularly critical for applications requiring high-quality surface finishes, such as luxury packaging, electronic components, and medical device manufacturing.

The machine's innovative dry bonding technology eliminates the need for solvent-based adhesives, making it an environmentally friendly choice while also reducing material costs by approximately 18% compared to traditional wet lamination processes. This is a significant advantage for companies looking to reduce their carbon footprint and comply with increasingly strict environmental regulations.

When you're working with heat-sensitive materials like thin films for electronic displays, traditional laminating equipment can cause warping or discoloration. This was a major challenge for a leading Asian electronics manufacturer specializing in flexible display components. After implementing Fangbang High Speed Dry Bonding Laminator, they were able to process these delicate materials at high speeds without any thermal damage, increasing their production capacity by 40% while maintaining their stringent quality standards.

Another compelling application is in the pharmaceutical packaging industry, where hygiene and precision are paramount. A North American pharmaceutical packaging company required a laminating solution that could handle sensitive materials while maintaining strict cleanliness standards. Fangbang's equipment, with its closed-loop material handling system and easy-clean design, not only met but exceeded their requirements, helping them achieve ISO 15378 certification for their packaging processes.

One of the most significant advantages of choosing Fangbang is the company's commitment to providing customized solutions rather than one-size-fits-all equipment. Unlike many competitors who offer standard machines with limited modification options, Fangbang works closely with each client to understand their unique production requirements and challenges.

For example, a European printing company specializing in high-end decorative laminates needed a solution that could handle a wide variety of material combinations with quick changeover times. Fangbang developed a customized version of their High Speed Dry Bonding Laminator with modular tooling systems that reduced changeover times from 45 minutes to just 12 minutes. This customization resulted in a 28% increase in their overall equipment effectiveness (OEE) rating.

"The flexibility of Fangbang's equipment has been instrumental in our ability to take on complex projects that our competitors can't handle," said the production manager of a leading flexible packaging manufacturer. "Their willingness to customize solutions based on our specific needs has given us a significant competitive advantage in the market."

In an era where manufacturing excellence is defined by both speed and precision, the Fangbang High Speed Dry Bonding Laminator represents the pinnacle of industrial laminating technology. Its combination of advanced engineering, intelligent design, and customizable features makes it the ideal solution for companies looking to stay ahead in today's competitive market.

Don't let outdated equipment hold back your production capabilities. Contact Fangbang today to schedule a personalized demonstration of their High Speed Dry Bonding Laminator and discover how it can transform your manufacturing processes. Our team of experts will work with you to develop a solution tailored to your specific requirements, helping you achieve new levels of efficiency and quality.

Visit our website to learn more about the complete range of Fangbang industrial laminating solutions and how they can benefit your business. The future of manufacturing is here—are you ready to embrace it?

Jan 29, 2026

High-Precision Slitting & Rewinding Machines - FANGBANG Industrial SolutionsJan 22, 2026

Why choose automatic Laminating MachinesJan 19, 2026

Electronic Axis Gravure Printing: Revolutionizing High-Speed Packaging Production