It is controlled centrally by PLC system and generally consists of unwinding section,infeed section,printing section,drying section, outfeed section, rewinding section and control section.

This machine is an ideal machine for printing paper cup, carton, paper bag, paper package, and so on.

The high-speed flexographic printing machine integrates servo-driven technology with 10-color printing capability, achieving 550m/min speed and 0.02mm registration accuracy. Its UV/IR dual curing system supports water-based, solvent-based, and LED inks for food-grade packaging. The machine features automatic plate changing (40% faster setup), AI color management, and IoT remote diagnostics. Equipped with web guiding and waste removal systems, it reduces material waste by 30%. Energy-efficient design cuts power consumption by 35%, ideal for flexible films, labels, and shrink sleeves. CE/ISO certified with 2-year warranty.

Separate single-station unwinding rollstand with hydraulic lifting device; 3“ pneumatic shaft for loading material; Automatically constant tension controller for unwinding tension control and EPC web guide control system for material alignment; alarm function for reminding replacing material, stopping-machine device for detecting material broken.

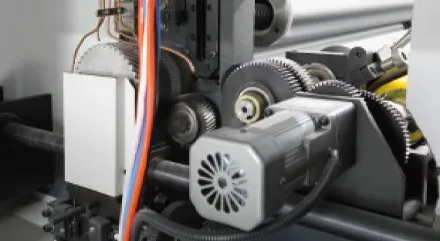

The machine is mainly controlled by inverter-fed motor with synchronization belt.

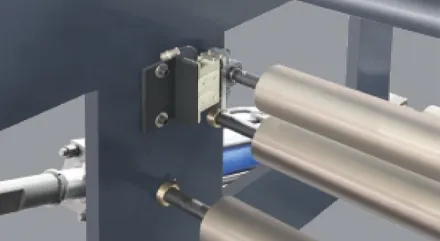

Double rubber nipper roller is used for paper feeding, whose pressure can be adjusted by pneumatic component;taper tension control system ensures the printing accuracy.

Ceramic anilox roller for ink transferring; single-blade reverse ink-scraping system;

pneumatic clutch pressure for anilox rollers and plate rollers. Automatic Preventing Clogging Function: when the machine stops, the anilox roller will rotate to prevent the ink on its surface from drying and blocking holes (meshes) on it.

Double rubber nipper roller is used for paper feeding of rewinder, whose pressure can be adjusted by pneumatic component; equip with picture color detection system (Kesai).

6.Single-station rewinding rollstand with hydraulic lifting device; 3" pneumatic shaft for loading material; stopping-machine device for detecting material broken.

7.Separate drying system (electric heating); I.R. short-wave heater drying system (the temperature is adjustable); hot air and natural air drying system including exhaust fan and blower; central Exhaust System (waste gas will be exhausted centrally by exhaust fan, it is ready by user).

8.The whole machine is centrally controlled by siemens PLC system, which has monitors the machine status;the running speed can be adjusted at multiple points.

| Model | RZJ-41000A | RZJ-41300A | RZJ-41500A |

| Max.Web Width | 1020mm | 1320mm | 1520mm |

| Max. Printing Width | 1000mm | 1300mm | 1500mm |

| Printing Repeat | 380-1200mm | 380-1600mm | 380-1600mm |

| Max. Unwinder Diameter | Φ1524mm | Φ1524mm | Φ1524mm |

| Max. Rewinder Diameter | Φ1524mm | Φ1524mm | Φ1524mm |

| Gearing | 1/8cp | 1/8cp | 1/8cp |

| Max. Printing Speed | 150m/min | 150m/min | 150m/min |

| Diameter of Web Roller | Φ100mm | Φ100mm | Φ100mm |

| Base Motor Power | 11kw-15kw | 15kw-18.5kw | 18kw-22kw |

| Ink | A. Environmentally friendly water-based ink B. UV ink |

A. Environmentally friendly water-based ink B. UV ink |

A. Environmentally friendly water-based ink B. UV ink |

| Drying Mode | A. Heat seal drying B. Infrared drying C. UV drying |

A. Heat seal drying B. Infrared drying C. UV drying |

A. Heat seal drying B. Infrared drying C. UV drying |

| Power Requirement | 380V3PH 50HZ | 380V 3PH 50HZ | 380V 3PH 50HZ |

Professional after-sales team provides round-the-clock online service

Comprehensive pre-shipment machine testing services

Dedicated solutions for gravure printing presses